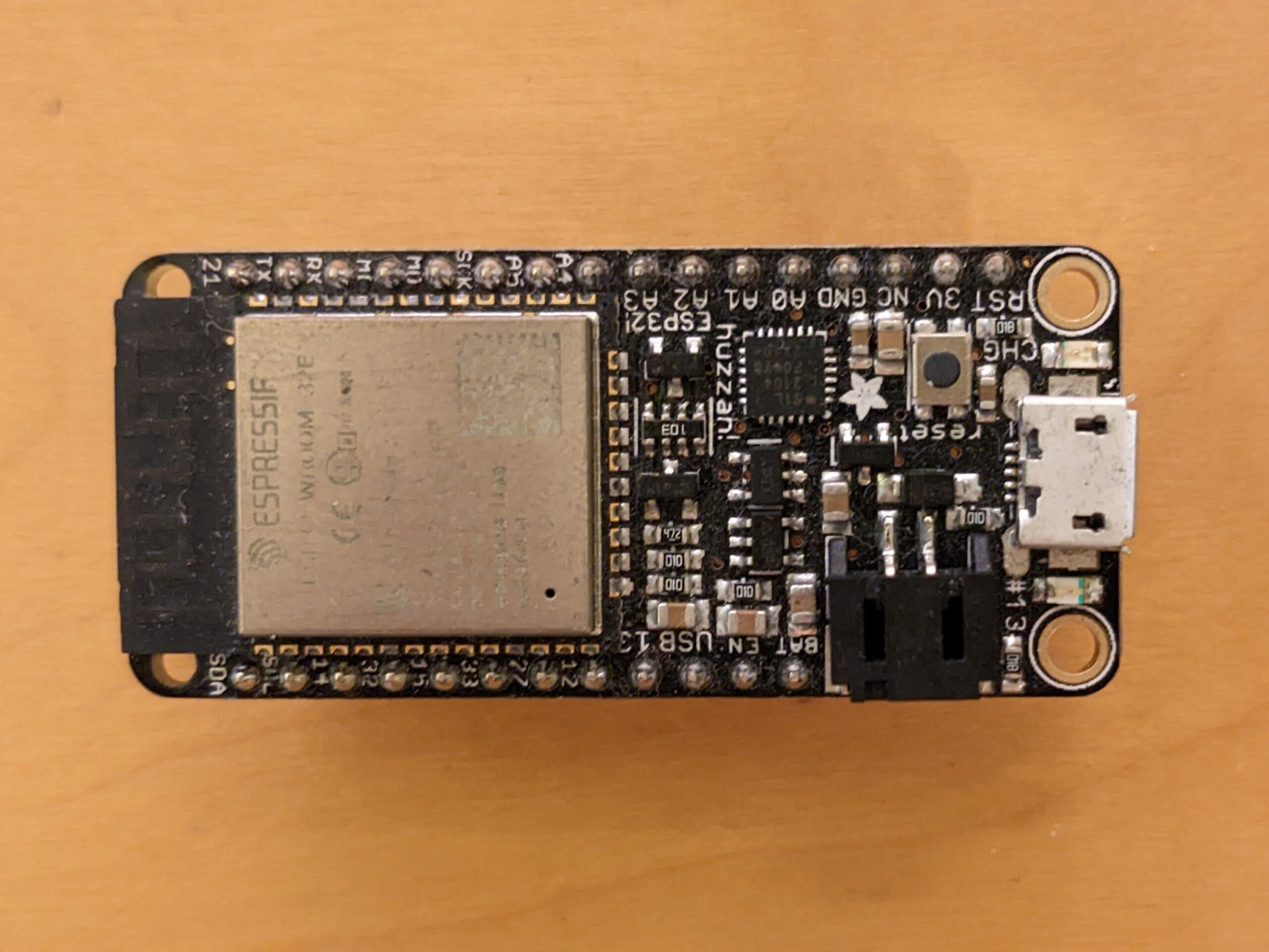

Huzzah32 ESP32: PWM Sounds using Micropython

Huzzah32 ESP32: PWM Sounds using Micropython Huzzah32 ESP32 has a lot of great features with Micropython. One of the simplest and most sensitively interesting projects is the PWM sounds using Micropython, which stands for Pulse Width Modulation, a technique for modulating pulse waves by varying their duty ratio, and is used in various electrical controls….